Insulated glazing

When multiple glass panes or "lites" are assembled into units, they are commonly referred to as insulated glass, double glazing, Double Glazed Units (UK and Europe) or Insulating Glass Units (IGU) (North America and Australia).

These units use the thermal and acoustic insulating properties of a gas (or vacuum) contained in the space formed by the unit. They can provide good insulation without sacrificing transparency (visual transmittance (VT)). Single glazed tinted and reflective glasses can provide similar thermal insulation, but for the same insulation performance are harder to see through and provide little protection against unwanted sound.

Most IGUs are double glazed, but IGUs with three sheets or more, i.e. "triple glazing" are becoming more common due to higher energy costs. Insulated glazing may be framed in a sash, frame or in a curtain wall.

Contents |

Comparison of IGU characteristics

IGUs are manufactured to varying degrees of performance, as shown in the table below.)

| Glazing assembly | U-factor | R-value | SHGC | VT | acoustic attenuation | ||

|---|---|---|---|---|---|---|---|

| unit -> | W/(K·m2) | BTU/(h·ft2·°F) | K·m2/W | h·ft2·°F/BTU | % | % | dbRW+ctr |

| standard double-pane IGU [1] | 2.84 | 0.50 | 0.35 | 2.0 | 76 | 81 | |

| Medium-SHGC, low-e[1] | 1.48 | 0.26 | 0.68 | 3.8 | 58 | 78 | |

| Triple glazed with glass, low-e[2](German passive house standard[3]) | 0.8 | 0.15 | 1.2 | 7 | 33...51 | 0.6 | 45 |

| For comparison: | |||||||

| single glass [1] | 6.25 | 1.10 | 0.16 | 0.90 | 87 | 90 | |

| standard wood wall, 2x6, R-19 fiberglass[4] | 0.49 | 0.09 | 2.06 | 11.7 | |||

Components

Glass

Glass is used to provide light and allow vision of things outside the place that is viewed from. While the composition and manufacturing of glass is covered elsewhere, for the purposes of this article, its importance to the construction is its dimensional stability over a wide temperature range. IGUs are manufactured with glass in range of thickness from 3 mm to 10 mm or more in special applications. Laminated or tempered glass may also be used as part of the construction. Most units are manufactured with the same thickness of glass used on both panes but special applications such as acoustic attenuation or security may require wide ranges of thicknesses to be incorporated in the same unit.

To reduce shear effects on the sealed unit (a major cause of premature failure), manufacturers use a rule of thumb that permits a difference of 1 mm between panes of glass used in the unit and still maintain the warranty for the unit. For example, a unit may be ordered with a 4 mm pane on the exterior and a 3 mm pane on the interior. These variations are allowed for architectural and cost reasons. Other combinations can be specified and produced but the manufacturer may reserve the right to limit the term of the warranty or refuse to warranty the unit altogether.

For ease of description the surfaces of a double paned unit are named according to the following convention: Surface #1 (facing outside), Surface #2 (inside of outside pane), Surface #3 (outside of inside pane) and Surface #4 (inside surface of inside pane). Applying the corresponding nomenclature for triple paned units results in surfaces #1 through #6.

The performance of glass can be modified through the use of the following:

Tinted glass

While clear glass is the most common glass component of IGUs, tinted glass may be used to reduce solar heat gain or as an architectural feature. The principal colors available are bronze, gray and green [5]. The degree of tint depends on both the composition of the glass and the thickness of the coating. Tinted glass is usually placed on the exterior of the IGU. It almost always requires heat-treatment to reduce potential thermal stress and breakage and tends to re-radiate the absorbed heat. [6]

Coated glass

The heat and sound insulation of glazing may also be improved by the use of a film or coating applied to its surface. This film is typically made of polyester or metal, and may give the window a reflective appearance or a one-way mirror effect. It may be used on single-glazed windows as an alternative to insulated glazing, or on surfaces #1, #2 or #3 (or combinations thereof) of insulated glazing to further improve its effectiveness.[1] Such coatings may reduce fading of fabric and improve safety in case of breakage.[2]. Glass performance is measured in two ways: Solar Heat Gain Co-efficient (SHGC), which expresses the proportion of incidental solar thermal radiation that is transmitted by the glass and Visible Transmittance, which describes the amount of visible light that is conducted through the glass between the exterior and interior surfaces. Both of these properties can be independently altered by different coatings.[7]

Low-emissivity glass

Low-emissivity (Low-E) glass has a thin coating, often of metal, on the glass within its airspace that reflects thermal radiation or inhibits its emission reducing heat transfer through the glass.

A basic low-e coating allows solar radiation to pass through into a room. Thus, the coating helps to reduce heat loss but allows the room to be warmed by direct sunshine. The low-e coating is usually on surface #3; if solar control is required then the coated surface is moved to surface #2 to reflect or absorb solar radiation. The change in location of the coating does not affect the insulating properties of the IGU, only the percentage of solar heat gain.

Further solar radiation control can be added through the use of tinted glass and/or metallic coatings [8]. Low-e glass reflects the radiation rather than absorbing it improving performance compared to the glass in a simple greenhouse. Its effect can be noticed by an increase in temperature of the inside glass surface and the reduction of condensation that would normally form on the unit because of a change in the dew point.

There are two types of low-e coatings available, "hard-coat" or pyrolytic and "soft-coat" or sputtered. Hard-coat glass is manufactured using the Atmospheric Pressure Chemical Vapor Deposition (APCVD) method of applying a doped tin composition to the glass surface as the glass sheets are being manufactured in the hot tin bath of a glass float plant, or alternatively in an offline furnace process. The tin bonds to the surface of the glass and forms a relatively thick coating. Hard-coat glass is considered a low to medium performance coating since the emissivity is greater (about 10 times) compared to the sputtered coating. The advantage of hard-coat glass is that it does not require special handling in the IGU assembly process to maintain the surface's coating integrity and does not scratch easily. It does require that the glass surface in contact with the spacer be abraded to improve adhesion of the sealant.

MSVD, or Magnetron Sputterering Vacuum Deposition (also known as "sputtering"), is the other technology used to manufacture Low-E glass. In MSVD, a metal or ceramic target bombarded with ions releases atoms to form a thin coating on a sheet of glass under high vacuum. The latest sputtered products are engineered to be increasingly more durable, approaching the durability of "hard coat" products. [9]

Sputter coated high performance low-e glass offers better performance when compared to hard coat glass. The sputtered coating is often less durable compared to pyrolytic coated glass, and may require special handling and storage for both the manufacturing process and IGU fabrication. Choosing a high performance low-e glass over a hard-coat glass improves thermal performance of the IGU by about 13%. [10]

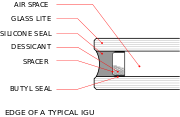

Spacer

The glass panes are separated by a "spacer". A spacer is the component, or piece, used in window manufacturing that separates the two panes of glass in an insulating glass (IG) system, and seals the airspace between them. Historically, spacers were made primarily of metal, which manufacturers thought provided more durability for their windows. However, metal spacers act as a heat conductor, undermining the ability of the IGU to reduce heat flow. This may result in water or ice forming at the bottom of the sealed unit because of the heating/cooling loss through the window. To reduce heat transfer through the spacer and increase overall thermal performance, the spacer may be constructed of a less-conductive material such as structural foam. [11]

Typically, spacers are filled with or contain desiccant to remove moisture trapped in the air space during manufacturing, preventing condensation from forming on surface #2 when the temperature falls below the dew point.

New technology has emerged to combat the heat loss from traditional spacer bars. The Keepheat Warm Edge Spacer[12], also known as the Triseal Super Spacer Bar, uses foam technology as opposed to a conductive metal, thus reducing noise by up to 2dB and heat by 15%.[13]

Construction

IGUs are manufactured on a made to order basis on factory production lines. The width and height dimensions, the thickness of the glass panes and the type of glass for each pane as well as the overall thickness of the unit must be supplied to the manufacturer. On the assembly line, spacers of specific thicknesses are cut and assembled into the required overall width and height dimensions and filled with desiccant. On a parallel line, glass panes are cut to size and washed to be optically clear. An adhesive sealant (polyisobutylene or PIB for short)is applied to the face of the spacer on each side and the panes pressed against the spacer. If the unit is gas filled, two holes are drilled into the spacer of the assembled unit, lines are attached to draw out the air out of the space and replaced with the desired gas - however the more modern technique is with the introduction of an online gas filler, which removes the need to drill holes in the spacer - The lines are then removed and holes sealed to contain the gas. The units are then sealed on the edge side using either polysulphide or silicone sealant or similar material to prevent humid outside air from entering the unit. The desiccant will remove traces of humidity from the air space so that no water appears on the inside faces of the glass panes facing the air space during cold weather. Some manufacturers have developed specific processes that combine the spacer and desiccant into a single step application system [14].

The double glazing in windows was invented in 1930s, was commonly available in USA in the 1950s as Thermopane, so after almost 79 years, the manufacturing process is well known. The brandname Thermopane has entered the vocabulary of the glazing industry as the equivalent name for an IGU. Materials which can be used for double glazing are versatile and include aluminium, PVC, and timber [15].

Thermal performance

The maximum insulating efficiency of a standard IGU is determined by the thickness of the space containing the gas or vacuum. Too little space between the panes of glass results in radiant heat loss between the panes (the inside surface of one pane cools the surface of the other pane) while too wide a gap results in convection current losses (gas begins to circulate because of temperature differences and transfers heat between the panes). For further information, see the article heat flow. Typically, most sealed units achieve maximum insulating values using a gas space of between 5/8 to 3/4” (16-19 mm) when measured at the centre of the IGU. When combined with the thickness of the glass panes being used, this can result in an overall thickness of the IGU of between 7/8 and 1” for 3 mm glass (22-25 mm) to 1 1/2” (28-31 mm ) for 1/4” plate glass.

IGU thickness is a compromise between maximizing insulating value and the ability of the framing system used to carry the unit. Some residential and most commercial glazing systems can accommodate the ideal thickness of a double paned unit. Issues arise with the use of triple glazing to further reduce heat loss in an IGU. The combination of thickness and weight results in units that are too unwieldy for most residential or commercial glazing systems, particularly if these panes are contained in moving frames or sashes.

These issues can be solved in various ways. Ideally, a perfect vacuum provides the most thermal insulation value. Alternatively, a technique called evacuated glazing can be used to drastically reduce heat transfer through convection and conduction.[16] These IG Units have most of the air removed from the space between the panes, leaving a partial vacuum. Similar techniques are also used in insulation products called vacuum insulated panels. In practice, however, these types of systems are not used commercially as the panel strength needed to counteract the effects of atmospheric pressure increases rapidly with the overall surface area of the unit and so the actual available viewing area through the glass is quite small.

A more practical alternative is to replace air in the space with a heavy gas that diffuses more slowly than oxygen and nitrogen. Slower diffusion leads to less convective heat transfer. Argon (argon has a thermal conductivity 67% that of air)[17], krypton (krypton has about half the conductivity of argon) or xenon to increase the insulating performance. These gases are used because they are non-toxic, clear, odorless, chemically inert, and commercially available because of their widespread application in industry. These gases have a higher density compared to air but have higher costs. In general, the more effective a fill gas is at its optimum thickness, the thinner the optimum thickness is. For example, the optimum thickness for krypton is lower than for argon, and lower for argon than for air.[18] However, since it is difficult to determine whether the gas in an IGU has become mixed with air at time of manufacture (or becomes mixed with air once installed), many designers prefer to use thicker gaps than would be optimum for the fill gas if it were pure. Argon is commonly used in insulated glazing as it is the most affordable. Krypton, which is considerably more expensive, is not generally used except to produce very thin double glazing units or relatively thin, or extremely high performance triple glazed units.[19] Xenon has found very little application in IGUs because of cost.[20]

Heat insulating properties

The effectiveness of insulated glass can be expressed as an R-value. The higher the R-value, the greater is its resistance to heat transfer. A standard IGU consisting of clear uncoated panes of glass (or lites) with air in the cavity between the lites has an R-value of 2, or 0.35 K·m2/W (2 h·ft2·°F/BTU).

Using imperial units, a rule of thumb in standard IGU construction is that each change in the component of the IGU results in an increase of 1 R-value to the efficiency of the unit. Adding Argon gas increases the efficiency to about R-3. Using low emissivity glass on surface #2 will add another R-value. Properly designed triple glazed IGUs with low emissivity coatings on surfaces #2 and #4 and filled with argon gas in the cavities result in IG units with R-values as high as R-5. Certain vacuum insulated glass units (VIG) or multi-chambered IG units using coated plastic films result in R-values as high as R-12.5 [21]

Acoustic insulating properties

In some situations the insulation is in reference to noise mitigation. In these circumstances a large air space improves the noise insulation quality or Sound transmission class. Asymmetric double glazing, using different thicknesses of glass rather than the conventional symmetrical systems (equal glass thicknesses used for both lites) will improve the acoustic attenuation properties of the IGU at the cost of longevity if the unit is used to separate exterior and interior environments. This is due to the differing thermal expansion rates of the glass being used and the shear stress placed on the edge and spacer sealants. If standard air spaces are used, sulfur hexafluoride is used to replace or augment an inert gas[22] and improve acoustical attenuation performance.

Longevity

The life of an IGU varies depending on the quality of materials used, workmanship and location of installation both in terms of facing direction and geographic location. IG units typically last from 10 to 25 years, with windows facing south (Northern Hemisphere) or the north (Southern Hemisphere) often lasting less than 12 years. IGUs typically carry a warranty for 10 to 20 years depending upon the manufacturer. If IGUs are altered (such as installation of a solar control film) the warranty may be voided by the manufacturer.

The Insulating Glass Manufacturers Alliance (IGMA)[23] undertook an extensive study to characterize the failures of commercial insulating glass units over a 25 year period.[24]

For a standard construction IG unit, condensation collects between the layers of glass when the perimeter seal has failed and when the desiccant has become saturated, and can only be eliminated by replacing the IGU. Seal failure and subsequent replacement results in a significant factor in the overall cost of owning IGUs.

In Canada, since the beginning of 1990, there are some companies offering restoration of failed IG units. They provide open ventilation to the atmosphere by drilling hole(s) in the glass and/or spacer. This solution often reverses the visible condensation, but cannot clean the interior surface of the glass and staining that may have occurred after long term exposure to moisture. They may offer a warranty from 5 to 20 years. This solution lowers the value of the glass a bit, but it can be a "green" solution when the window is still in good condition. If the IG unit had a gas fill (e.g. argon or krypton or a mixture) the gas is naturally dissipated and the R-value suffers.

Since 2004, there are also some companies offering the same restoration process for failed double glazed units in the UK, and there is one company offering restoration of failed IG units in Ireland since 2010.

Estimating heat loss from double glazed window

Estimating the rate of heat loss is essential in choosing which type of double glazed window to be used in a building to maintain desired thermal comfort. Relevant data and calculation from different calculations are listed below:

Required data

To properly estimate the heat loss through any window, one needs to take into account not only the pane and gap, but also the thermal properties of sash, frame and sill. Thermal bridging through any of these can lead to huge energy losses. Also, better is to use the overall window performance values, rather than just that at the glass center.

- Thermal resistance of the glass used

- Physical properties of the gas used in between the gap (such as density, heat capacity and k value)

- Dimension of the double glazed glass

Calculation

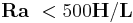

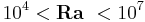

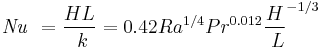

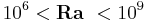

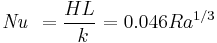

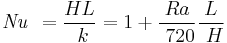

Table 1.1 Relevant correlations to calculate natural convection inside the window gap[25]

| Condition | Correlation |

|---|---|

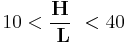

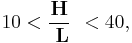

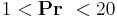

|

|

|

|

|

|

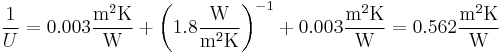

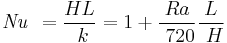

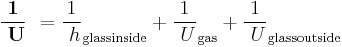

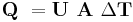

By using natural convection correlations that fulfil the given criteria; the overall heat transfer coefficient can be calculated by using equation (1). Hence, to estimate the overall heat loss, equation (2) will be used

_______(1)

_______(1)

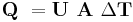

_______(2)

_______(2)

Example calculation of heat loss from double glazed window

Q. Estimate the heat transfer coefficient and thermal resistance of the air gap in a double glazed window. Assume that the outer surface of the inner glass pane is at 10 oC and that the inner surface of the outer glass pane is at -10 oC. Assume that the window is 2m tall (H) and 2 m wide, and that the gap between the glass panes is 1.5 cm (L). How does the thermal resistance compare to glass 0.003 m2K/W and curtains ~ 0.5 m2K/W? If air is a good insulator, why is such a small air gap used?

Physical property of air

| μ | 1.65 x 10-5 | Pa s |

| Cp | 1050 | J/kg K |

| k | 0.0242 | W/m K |

Solution

First calculate  ,

,  ,

,  and

and  to determine which natural convection correlation to use.

to determine which natural convection correlation to use.

|

133.33 |

|

6.67 x 104 |

|

1.10 x 104 |

|

6.94 x 10-1 |

Therefore, the best correlation that fulfill the calculated condition is  We then proceed to calculate the heat transfer coefficient of the gas in between the glass. Be reminded that the

We then proceed to calculate the heat transfer coefficient of the gas in between the glass. Be reminded that the  is the width of the gap and the

is the width of the gap and the  is the height of the window. Calculating the Nusselt number will yield 1.11 and further calculating will yield 'h' value of 1.80 W/m^2 K.

is the height of the window. Calculating the Nusselt number will yield 1.11 and further calculating will yield 'h' value of 1.80 W/m^2 K.

Since we've known the thermal resistance value of each glass, we can proceed to calculate the overall heat transfer coefficient of the double glazed window by using equation 2.

To calculate the overall heat loss, we will use equation 2.

References

- ↑ 1.0 1.1 1.2 Krigger, J., Dorsi, C.: Residential Energy, 4th ed., page 121

- ↑ http://buildingsdatabook.eren.doe.gov/TableView.aspx?table=5.2.8

- ↑ http://www.hornbach.de/projects/de/html/cont_energiespecial_energie_verbrauchsenken_fenster.phtml

- ↑ Krigger, J., Dorsi, C.: Residential Energy, 4th ed., page 121. Note: This is less than R-19, since it refers to the whole-wall R-value

- ↑ http://products.construction.com/Manufacturer/PPG-Architectural-Glass-NST510/products/PPG-Architectural-Glass-Series---Introduction-NST15772-p

- ↑ http://na.en.sunguardglass.com/SpecificationsResources/TechnicalLibrary/TechnicalInformation/index.htm

- ↑ Windows Energy Ratings Scheme - WERS

- ↑ http://corporateportal.ppg.com/NR/rdonlyres/343C1D95-748C-4572-B3BB-E5483F4A3AFE/0/5075PResidentialComparisonSheet.pdf

- ↑ http://www.guardian.com/en/na/gp_014986.html

- ↑ http://corporateportal.ppg.com/NR/rdonlyres/343C1D95-748C-4572-B3BB-E5483F4A3AFE/0/5075PResidentialComparisonSheet.pdf

- ↑ Edgetech I.G., Does the spacer really matter?

- ↑ Manufacturers AC Yule - http://www.acyule.com/page-20070724-114107.html

- ↑ Triseal Spacer Bar from Central Scotland Joinery - http://www.centralscotlandjoinery.co.uk/triseal/

- ↑ http://www.tremcoeurope.com/Datasheets/Pdf/t4041.pdf

- ↑ http://casverwindowsystems.com.au/Timber-Double-Glazing

- ↑ Development and quality control of vacuum glazing by N. Ng and L. So; University of Sydney

- ↑ "Thermal Conductivity of Some Common Materials". www.engineeringtoolbox.com. http://www.engineeringtoolbox.com/thermal-conductivity-d_429.html.

- ↑ ASHRAE Handbook, Volume 1, Fundamentals, 1993

- ↑ http://www.southwall.com/southwall/Home/Products/Residential/HeatMirrorInsulatingGlass.html

- ↑ http://www.ktu.lt/ultra/journal/pdf_51_2/51-2004-Vol.2_01-J.Butkus.pdf

- ↑ http://www.southwall.com/southwall/Home/Products/Residential/HeatMirrorInsulatingGlass.html

- ↑ http://books.google.com/books?id=bqUxCGJd0owC&pg=PA504&lpg=PA504&dq=hexafluoride+insulating+glass&source=web&ots=niJxrJZMBa&sig=DQwDhsPWasPns4IgA4tJtyR_YXs&hl=en&sa=X&oi=book_result&resnum=1&ct=result

- ↑ http://www.igmaonline.org

- ↑ http://docs.google.com/viewer?a=v&q=cache%3AuJBE0li3Xd4J%3Awww.ornl.gov%2Fsci%2Fbuildings%2F2010%2FSession%2520PDFs%2F66_New.pdf+25+year+field+correlation+study+IG&hl=en&gl=us&sig=AHIEtbRkQ77HMBM0XQFqhczDrEgcPZE8HQ&pli=1

- ↑ Kavanagh.J, 'Heat Transfer, Natural Convection' March 2008, Department Of Chemical Engineering, University of Sydney.

6.^ Handbook of Chemistry & Physics, 62ed, CRC Press, ISBN-0-8493-0462-8

See also

|

|||||||||||||||||||||||